Inova test rigs can be used to test a wide variety of steering systems and their components, including I-shafts, electric or electro/ electro-hydraulic power assisted gears and electrically powered column drives. The test rigs can be combined with temperature chambers capable of simulating extreme use conditions, such as a cold start on a freezing winter morning in Scandinavia with temperatures plummeting to -40°C or extended operation in extreme heat over 100°C.

Test rigs communicate with the test specimen via standard car interfaces, including Can, CanFD and Flexray, while interaction with other car systems can be modelled through Restbus simulation.

Inova has rich experience in designing and developing custom and special-purpose systems, including in-production dynamic load performance comparisons against reference standards. (Special test rigs were developed for testing by production. Vibrations of steering body are measured by dynamic loading and compared with “mother” frequency spectra.)

- Durability tests

- Steering functional parameters testing

- Dynamic testing of I-shafts, electrically powered column drives or steering wheel adjusting systems

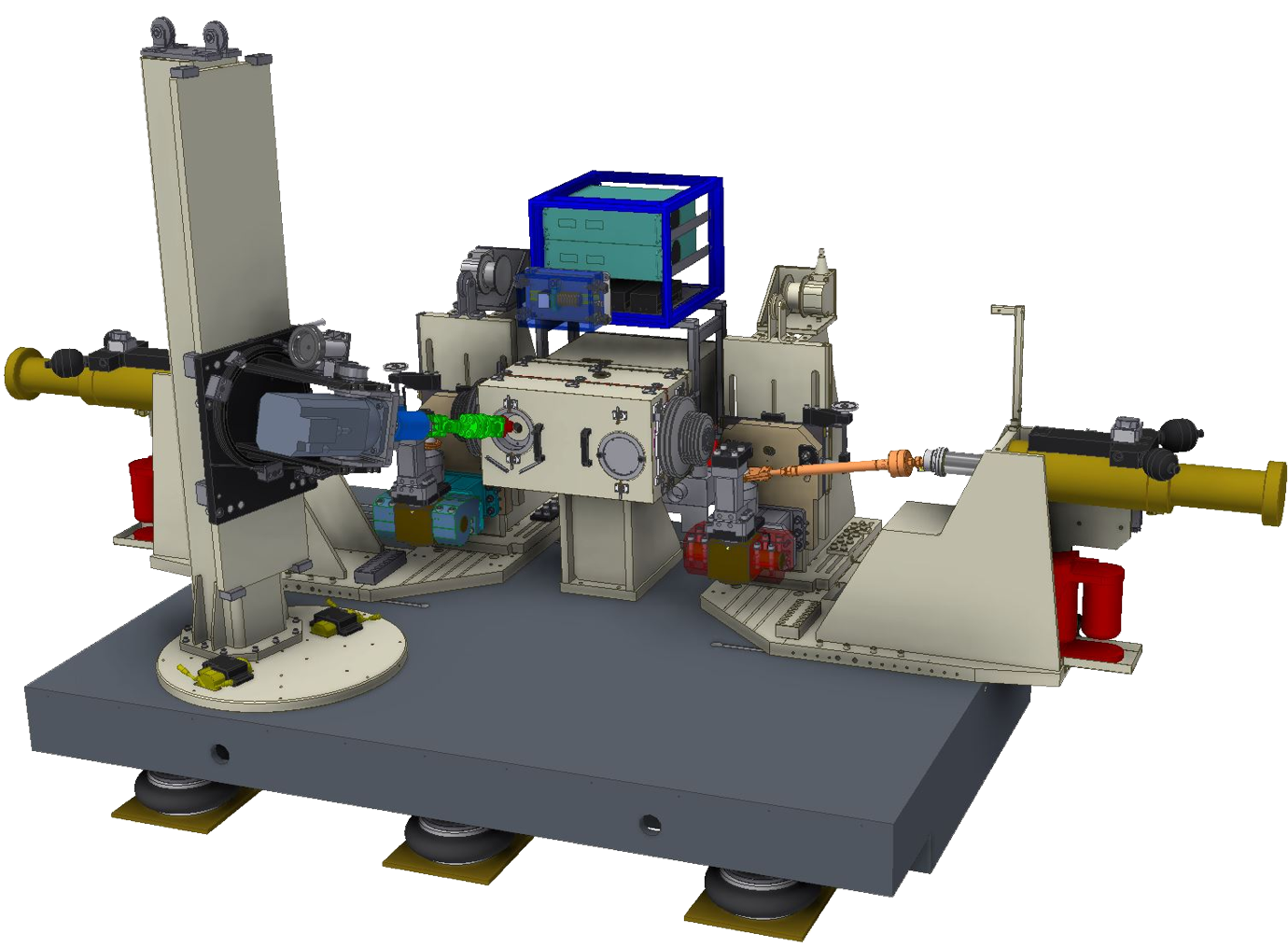

- Durability test rig – with or without dynamic vertical wheel motion simulation

- Performance test rig – comprehensive testing of steering system performance and parameters

- In-production benchmark system – comparison of products being manufactured against reference standards

- Durability test rig for electrically powered column drives

- I-shaft durability test rig – rotation, torsion and axial force testing

- Test rig for dynamic steering wheel adjusting system testing

- EU3000 RTC advanced proprietary test software suite

- Inova multichannel control system

- Backlash-free ball joints

- Can, CanFD and Flexray interface, Restbus simulation

- Linear and torque hydraulic actuators with hydrostatic bearings

- Electric rotary and linear drives with high-precision controls

- Temperature chambers

Heavy Equipment

Heavy Equipment Automotive

Automotive