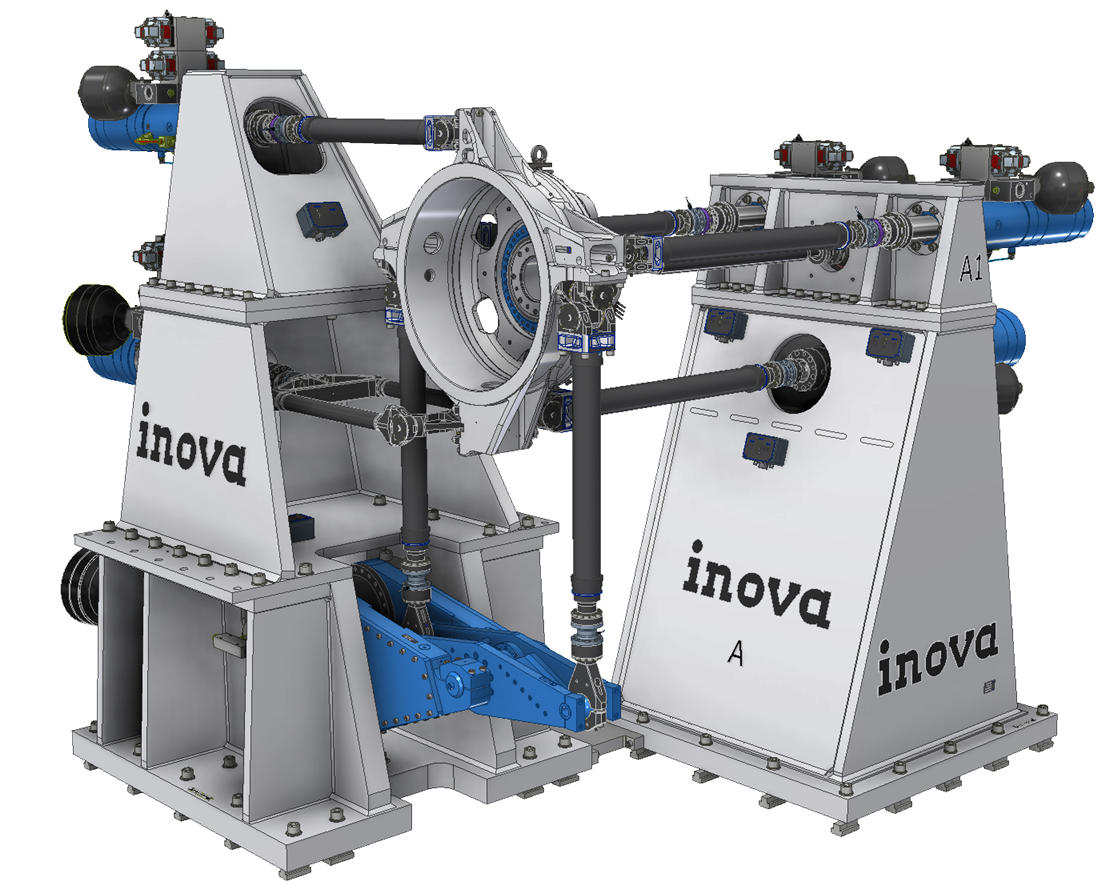

Road vehicle axles or car/ car components are typically tested using advanced multiaxial systems with loading vectors acting on wheels or adapters (dummy rims) fixed instead of wheels. INOVA provides a portfolio of pre-engineered or custom-made solutions featuring robust and reliable components, such as Inova Hydrostatic cylinders, ball joint, load chain, mechanical components but also the base block, power pack station, accumulator station, hydraulic manifolds and temperature chamber.

The systems’ ingenious design provides from 2/4-poster systems for motorcycle tests to 4/7-poster setups for car testing and x-posters for truck testing – and adaptability for special purpose vehicles, such as tractors. In addition, the systems are capable of recording live dynamic test signals measured on driving cars or motorbikes.

INOVA Axle Test Rigs are designed for high speeds and accelerations, boasting precise control and accurate loading thanks to INOVA iteration control. Moreover, owing to their very low noise levels the systems are well suited for specimen noise characteristics testing.

- Loading of wheels by vertical actuators – 2/4-poster (motor-bike), 4/7-poster (cars) or X-poster (trucks) setups

- 4 Poster system with full electric Cylinders 40kN, 4m/s

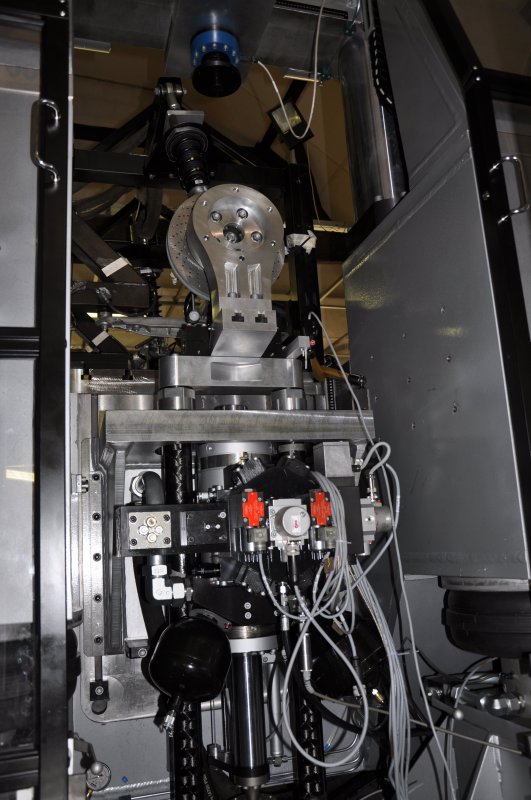

- Axle testing with up to 6 DOF loading of every wheel (dummy rim). Additional rotation of wheels and controlled steering drive possible

- Car testing with four 6 DOF loading corners and possible additional linear and torsional forces

- Designs with single or multiple DOF loading are available according to the intended use

- Testing at high and low temperatures

- 4/7-poster systems – vertical loading of wheels/chassis

- 1 × 6 DOF or 2 × 6 DOF test rig for half-axle of axle testing, optionally with wheel rotation functionality

- 4 × 6 DOF car test rig, optionally with linear or torsional loading functionality

- Special purpose uni- or multi- axial test rigs capable of simulating wheel loads or transfer of load forces by dummy rims

- Temperature chamber for tests at high or low temperatures

- INOVA multichannel high-speed control electronics

- Zero-backlash ball and cardan joints

- Iterations software package

- Hydraulic actuators with hydrostatic bearings and pre-loaded hydraulic actuators

- Linear guides with hydrostatic bearings

- Levers with hydrostatic bearings

- Lightweight aluminium and carbon components

- Cardan shafts for rotation testing

- Dummy rims

Heavy Equipment

Heavy Equipment Automotive

Automotive